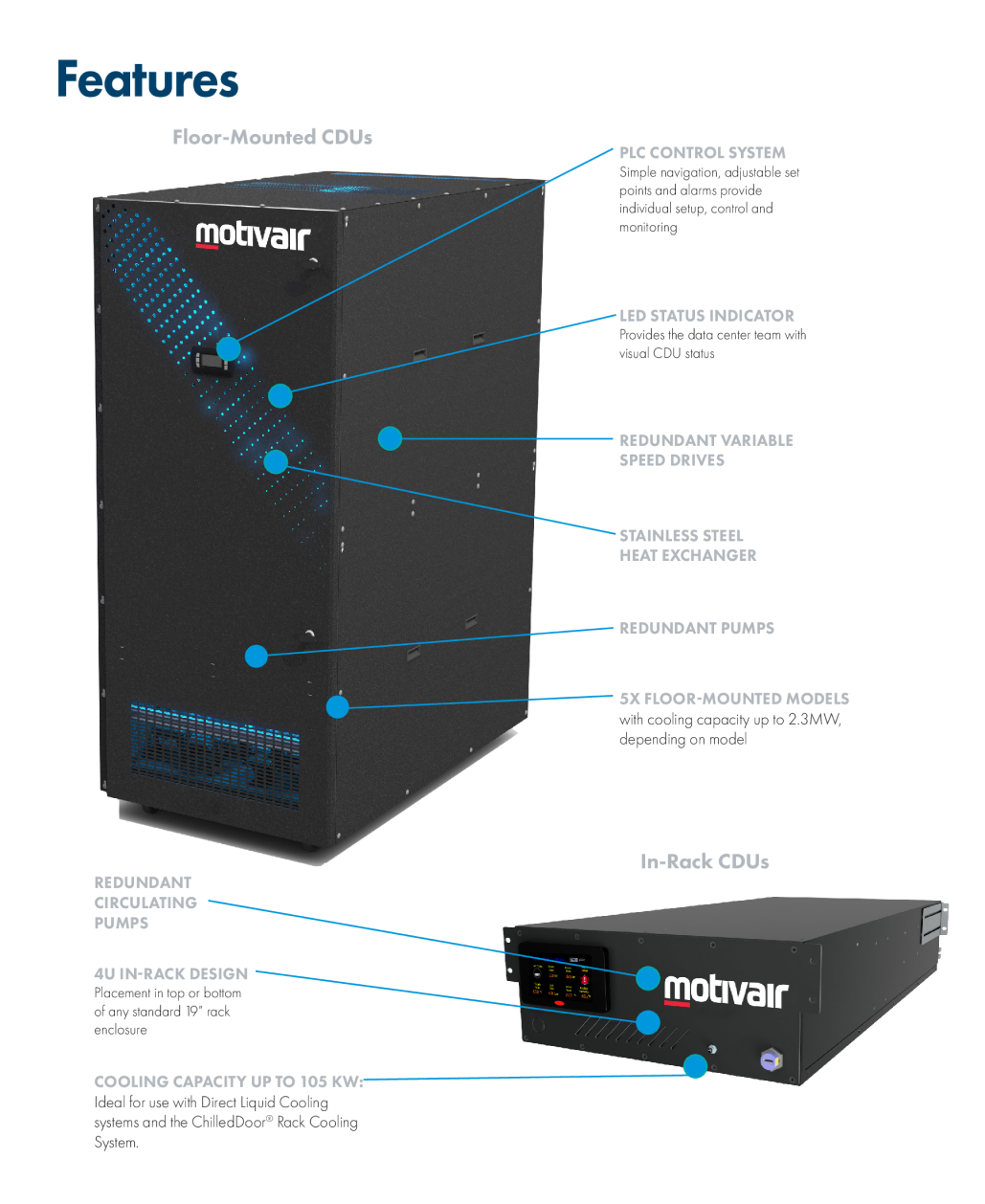

The Motivair® Coolant Distribution Unit (CDU) creates an isolated water loop and pumps this through the cooling system to operate at maximum efficiency. It automatically adjusts the coolant flow and temperature to provide 100% sensible cooling up to 2.3MW, depending on the model.

Each CDU uses a stainless-steel heat exchanger, which transfers the heat removed from the IT equipment in the secondary loop to the primary (building) chilled water supply. The primary chilled water supply can be a chiller, cooling tower, or natural resource. The redundant dual pumps deliver a secondary coolant loop with water supply temperatures ranging from 55F - 113F+ (W1- W5), which removes up to 2.3MW of IT equipment waste heat. Each CDU precisely controls required coolant flow based on IT cooling system needs. A complete range of CDUs with varying capacities allow for flexibility in design to best fit your application.

A modulating 2-way valve constantly adjusts the CDU cooling capacity based on IT demand. Operation is completely automatic with adjustable water temperature set points, dew point control and alarm thresholds that are easily accessible through the PLC control system mounted on the front of the CDU. A powerful PLC controls the entire CDU operation and provides remote control and communication via BACnet MS/ TP, BACnet IP, Modbus, or LON.

| Models | MCDU 4U | MCDU - 15 | MCDU - 25 | MCDU - 40 | MCDU-50 | MCDU-60 |

|---|---|---|---|---|---|---|

| Rated Cooling Capacities (kW)*: | ||||||

| Primary (Building) Supply @ 90F Secondary Supply/Return 25% PG @ 113F/149F | 102 | 310 | 625 | 1250 | 1725 | 2350 |

| Primary (Building) Supply @ 90F Secondary Supply/Return 25% PG @ 112F/122F | 28 | 85 | 170 | 337 | 478 | 633 |

| Primary (Building) Supply @ 45F Secondary Supply/Return @ 60F/84F | 70** | 210 | 410 | 840 | 1190 | 1575 |

| Coolant Fluids Available (Type)***: | Water, Glycol | Water, Glycol | Water, Glycol | Water, Glycol | Water, Glycol | Water, Glycol |

| Nominal [Primary | Secondary] Flowrate (GPM | GPM): | 30 | 20 | 90 | 60 | 185 | 120 | 420 | 240 | 420 | 340 | 800 | 450 |

| Primary & Secondary Connections (Inch)****: | 1-1/2” | 1-1/2” | 2-1/2” | 4” | 4” | 6” |

| Primary & Secondary Connection Locations (Type): | Rear | Top/Bottom | Top/Bottom | Top/Bottom | Top/Bottom | Bottom |

| Nominal Available Pump Head Pressure (Psi): | 15 | 25 | 37 | 32 | 30 | 32 |

| Number of Pumps (Std.|Optional): | 2 | 2|1 | 2|1 | 2|1 | 2|1 | 2|1 |

| Integrated Variable Speed Drives (VFD’s): | √ | √ | √ | √ | √ | √ |

| Number of Power Feeds (Qty.): | 2 | 2 | 2 | 2 | 2 | 2 |

| MCDU Dimensions (Inch): | ||||||

| Height: | 7” | 73-5/8” | 73-5/8” | 80-1/4” | 80-1/4” | 98-3/8” |

| Length: | 37” | 42-1/2” | 42-1/2” | 60-1/4” | 60-1/4” | 63 |

| Width: | 17-3/4” | 31-1/2” | 31-1/2” | 35-1/2” | 35-1/2” | 48-1/8” |

| Electrical Power Supply Options Available (V/Ph/Hz): | ||||||

| 200-240V/1Ph/50-60HZ | √ | |||||

| 230V, 460V, 575V/3PH/60HZ | √ | √ | √ | √ | √ | |

| 400V/3PH/50HZ | √ | √ | √ | √ | √ | |

| Redundant A/B Power Connections | √ | √ | √ | √ | √ | √ |

| Full Load Amps (FLA) (460V/3PH/60HZ): | 3.5***** | 4.8 | 11 | 19 | 24 | 35 |

| PLC Controls: | √ | √ | √ | √ | √ | √ |

| Communication Platforms Available (Type): | BACnet, SNMP, (optional) Modbus | BACnet, SNMP, Modbus | BACnet, SNMP, Modbus | BACnet, SNMP, Modbus | BACnet, SNMP, Modbus | BACnet, SNMP, Modbus |

| Sound Data Rated at 3 ft [1m] (dBa): | <55 dBA | <64 dBA | <68 dBA | <70 dBA | <75 dBA | <72 dBA |

| Safety Approvals: | UL/CSA/CE | UL/CSA/CE | UL/CSA/CE | UL/CSA/CE | UL/CSA/CE | UL/CSA/CE |

| Leak Detection (WDS Single|Redundant): | Std.|Optional | Std.|N/A | Std.|N/A | Std.|Optional | Std.|Optional | Std.|Optional |

| PLC Controls: | √ | √ | √ | √ | √ | √ |

| PLC Controls: | N/A | N/A | √ | √ | √ | Standard |

| PLC Controls: | Standard | N/A | N/A | √ | √ | √ |